behind our jewellery

OUR PRODUCTION

WAEKURA IN 3 STEPS

Find out what lies behind the brand, from inspiration to jewellery production.

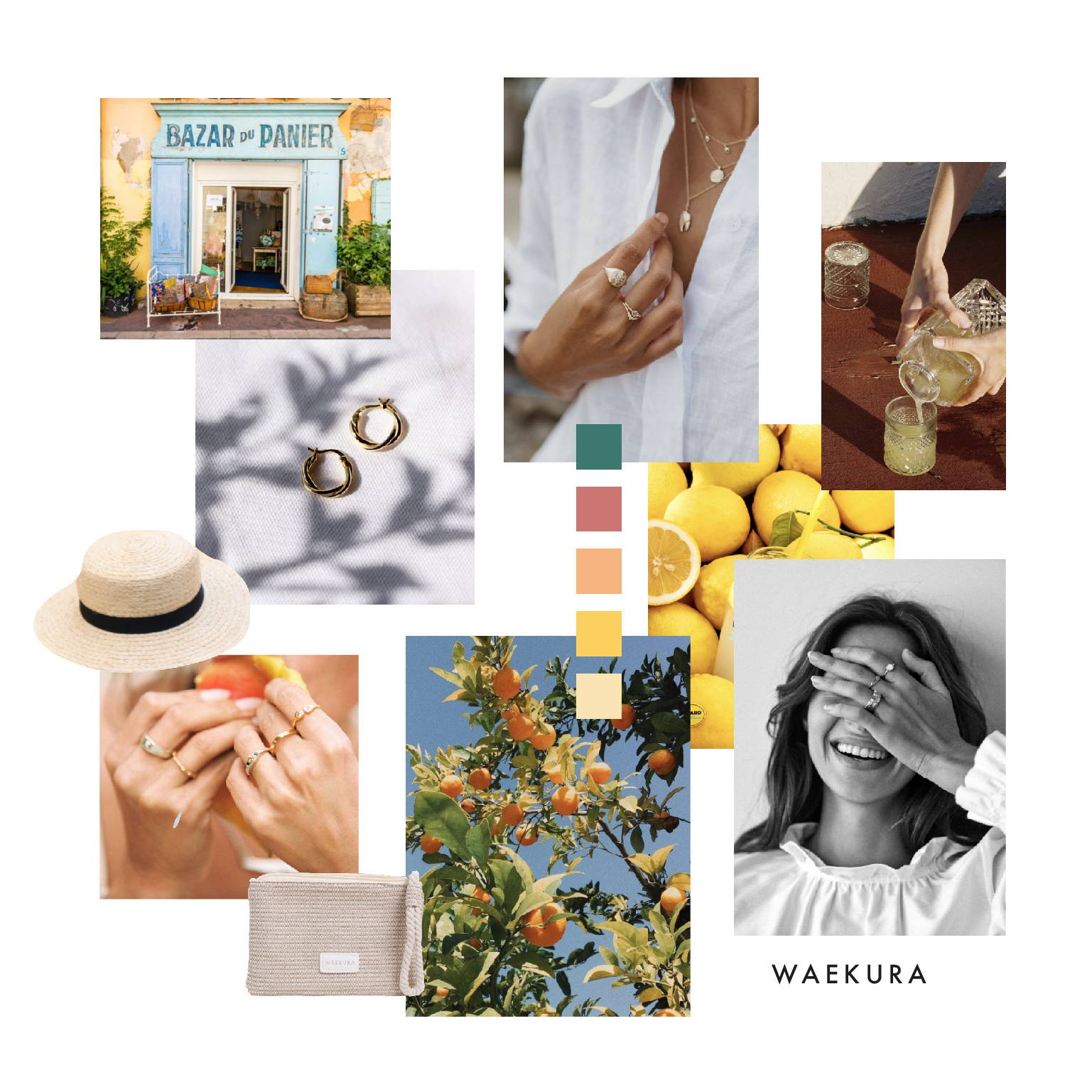

STEP 1: INSPIRATIONS

Each collection starts with an inspiration. A shape, an atmosphere or a person can inspire me. I also spend a lot of time on the internet scanning trends around the world and on social networks which are full of inspiring people and worlds. Once I have noted down the ideas, according to the season and the holidays, I create a moodboard in accordance with my inspirations, which gives birth to a universe in which the collection is anchored. Colours, shapes, key words, images, poses... The process of creating the jewellery comes second, once the theme of the collection has been defined.

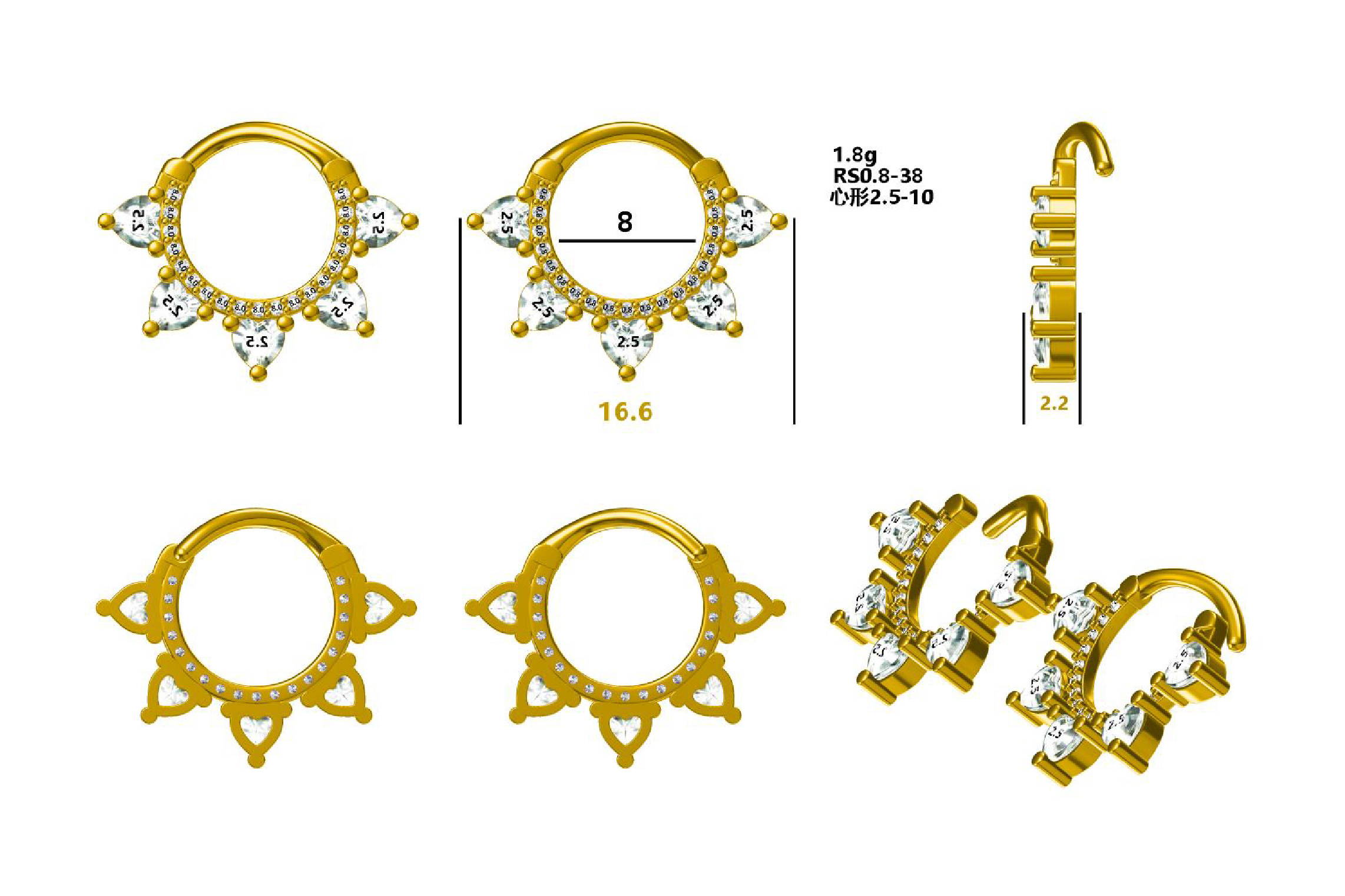

STAGE 2: DESIGN

Make way for the jewellery! According to your requests and the trends, the first designs are created. The partner workshops help me to design the 3D drawings to better imagine the jewellery. The adjustments are numerous: diameters, weight finishes, stones, closures or lengths. Today, 95% of the models are ours! We can now produce our own pieces because we have reached the minimum for custom moulds. In China, Spain, France and Germany, we choose workshops according to their know-how, in compliance with European social and environmental standards. The main thing: jewellery that is as beautiful as it is well produced and resistant. The gold plating is 100% done in Paris, a few minutes away from our offices!

STEP 3: COMMUNICATION AND DISPATCH

Once the jewels were collected, one of my favourite parts: the shooting! An article is available on the backstage and the realizations. For the engraving, we program your texts, drawings or any other request on a software. On the logistic side, Philip and Emmy take care of putting everything online, preparing the website, the codes for the shipments... Did you know that all your orders leave from our offices? Everything is packaged and sent to our logistics warehouse, located a few minutes from Paris. Once your orders have arrived, the warehouse teams put them in their shipping boxes with postal labels. Finally, your orders hit the road before arriving in your mailboxes!

BEHIND THE SCENES AT WAEKURA

FOCUS ON PRODUCTION

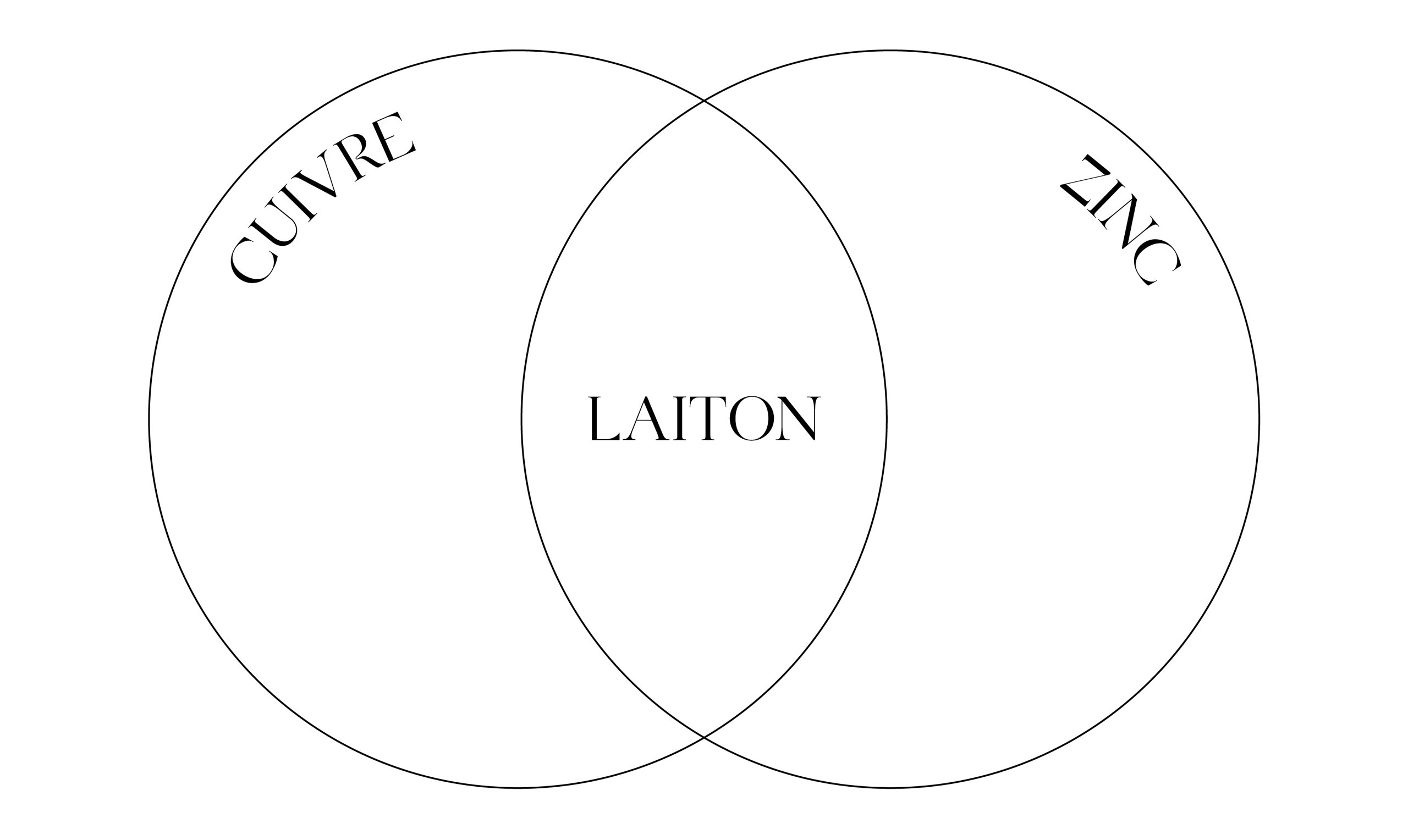

brass

After the design of the jewel, a wax mould is printed in 3D. The parts are assembled on a "wax tree" on which the setting is done. The brass alloy is cast and cooled, the brass jewellery shaft is made! This is followed by polishing, cutting, soldering, vibrating... and quality controls at each stage.

Brass is an alloy of copper and zinc. All our jewellery is made of 3 micron gold plating and shaped on a brass base.

We use it for several reasons:

It is malleable, anallergic and does not oxidise; it is resistant, and cis one of the most important metals which best supports plating

After receiving the brass parts, we send them to our gilder in Paris.

plating

All our jewellery is gold-plated in France. There is a specific definition and legislation concerning gold plating. It imposes a minimum thickness of 3 microns to be able to benefit from the designation gold plated on jewellery in France. First, the gilder cleans the pieces by ultrasound. Totally clean, they are finally ready to receive their treatment. The jewellery is then dipped in a bath using an electrolytic process (electroplating). A layer of gold of 3 microns, for our jewellery, then covers the metal. The bath lasts more or less time depending on the surface to be gilded and the desired thickness.

Gold plating is much stronger than gold-plated brass (almost 10 times thinner). All our jewellery is gold-plated in France. That's the most important thing about gold-plated jewellery, isn't it?

Where does the gold come from?

We supply you with a Swiss company, certified 29 times: on ecology, working conditions, recycling.

We do our utmost to produce as ethically as possible.

To find out more about our Parisian gilder, click here:

ASSEMBLY, MOUNTING AND ENGRAVING

Once our beautiful gold-plated jewellery has been received at the office, I assemble certain models if necessary (pearls or clasps, for example). As for the engraving, we program your texts, drawings or any other request on a software. After adjusting a few machine parameters, the diamond tip is placed on the chosen piece of jewellery to dig into the material. We do all the engraving ourselves, so you can have two slightly different models! You can also have the engraving done at the point of sale, in just a few minutes, directly with our sales consultants!

ASSEMBLY, MOUNTING AND ENGRAVING

Once our beautiful gold-plated jewellery has been received at the office, I assemble certain models if necessary (pearls or clasps, for example). As for the engraving, we program your texts, drawings or any other request on a software. After adjusting a few machine parameters, the diamond tip is placed on the chosen piece of jewellery to dig into the material. We do all the engraving ourselves, so you can have two slightly different models! You can also have the engraving done at the point of sale, in just a few minutes, directly with our sales consultants.

countries of manufacture

TRANSPARENCY, REAL

Why several countries? Because each one has its own know-how! France is perfect for stamping and well known for plating. They also do the designs, brass stamping, soldering, mounting, rhodium plating and treatment. China for the clasps and bases (our creoles are ultra strong!), Spain for the mini parts (the rings and the brackets), and Germany for the chains. All our workshops are certified and comply with European standards. They are members of the BSCI and the Responsible Jewellery Council (RJC). This allows us to control the production process as much as possible and to offer you the best possible service. offer the best.

With little production outside France, we can claim the "Made in France" appellation. Nevertheless, we find it more transparent to tell you everything, we are proud of the workshops we work with! In 2021 it is possible to property to produce, to offer fair prices, models of our own (and not just wholesalers) with impeccable quality.

If you have any questions, please do not hesitate to send directly to the address : [email protected]

EACH COUNTRY HAS ITS OWN KNOW-HOW!

After Paris, we send our models to different workshops to create the moulds and our brass parts. We choose the most suitable workshop according to its technology and know-how, in compliance with European social and environmental standards.

"WHY NOT A 100% MADE IN FRANCE PRODUCTION?

We work with workshops all over the world that are renowned for their expertise. The quality of the jewellery is essential for us, so it is obvious to choose the best!

IN ORDER TO OFFER YOU THE BEST, OUR WORKSHOPS :

COMPLY WITH EUROPEAN STANDARDS

IN ORDER TO OFFER YOU THE BEST, OUR WORKSHOPS :

COMPLY WITH EUROPEAN STANDARDS

OUR COMMITMENT

We are not perfect (yet) but we are doing everything we can to get closer!

The 2020 covid break allowed us to rework our production and to get closer to new suppliers

(even) more responsible. We want to do good and beautiful things! For a more responsible consumption, here are our actions.

ECOLOGY

From the jewellery packaging to the shipping box, we have done our utmost to optimise!

For several months now, our boxes have been 100% recyclable and we are working with a new mill that has FCS accreditation. This environmental label aims to ensure that the production of wood-based products (and therefore our paper for the boxes) respects procedures guaranteeing sustainable forest management. Boxes, small and medium sized boxes... all our packaging is certified. The pouches are also recyclable and unbleached.

As for our shipping boxes, we also wanted to do our best. We have also chosen the lightest possible FCS box to avoid over-consumption of CO2, which does not prevent it from being strong enough to protect your order.

It is printed with water-based, solvent-free inks, which makes it 100% recyclable.

Our packaging is not (to our great regret) made in France (due to sourcing problems and minimum orders to start production). On the other hand, we control everything and all our partners meet the requirements of European Union labour law.

Doing your best to have a as responsible as possible

Working with partners to labels certified and trusted

Focus on employees

and productions as close as possible